Multiwir MX packing

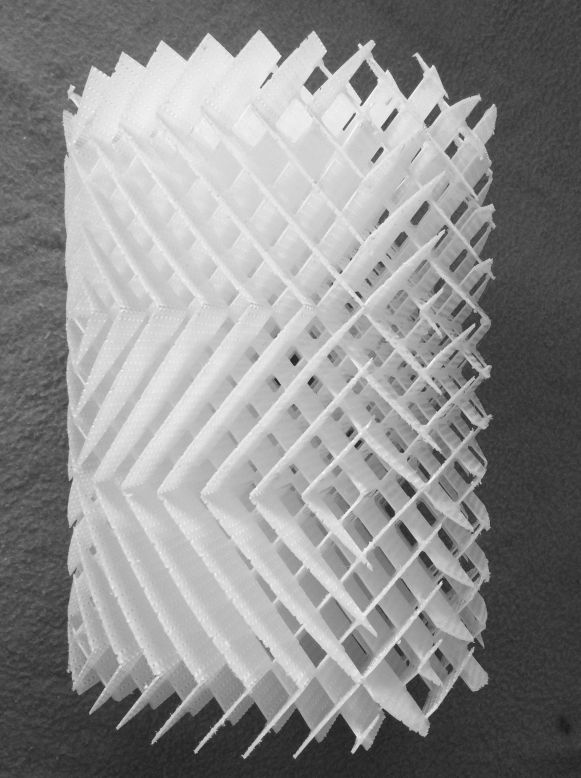

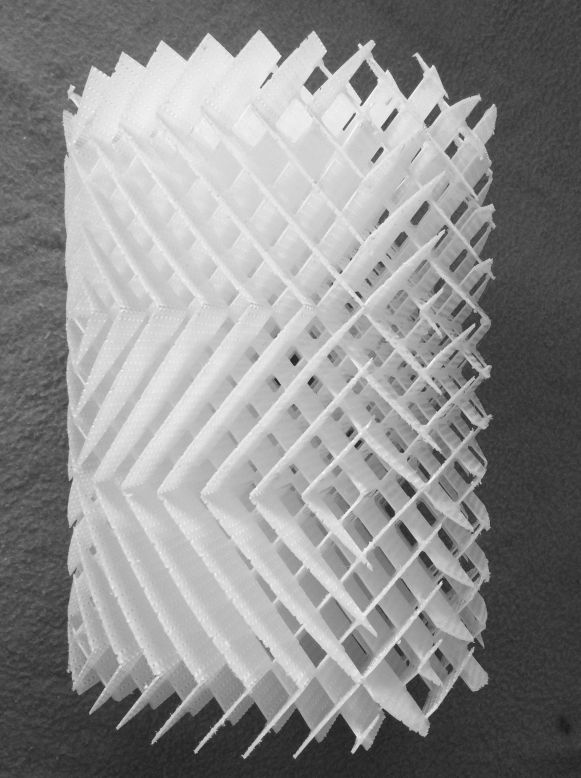

The effectiveness of the absorption process depends to a large extent on the correct distribution of liquid on the surface of the packing. The existence of dry packing elements and the “channeling” process, i.e. the formation of a straight liquid flow bypassing the packing structure, which happens to practically all types of random packings, significantly reduce the mass transfer coefficients. In order to achieve the optimum liquid cover, a special type of Multiwir packing, named MX packing, has been developed. The Multiwir MX structured packing, with a specific surface area of 90 m2/m3, is made of perforated polypropylene slats bent at an angle of 75o at regular length intervals. Perforations and bends ensure uniform flow of liquid on the entire surface of the packing from both sides of the slats even in the case of very low gas velocities.

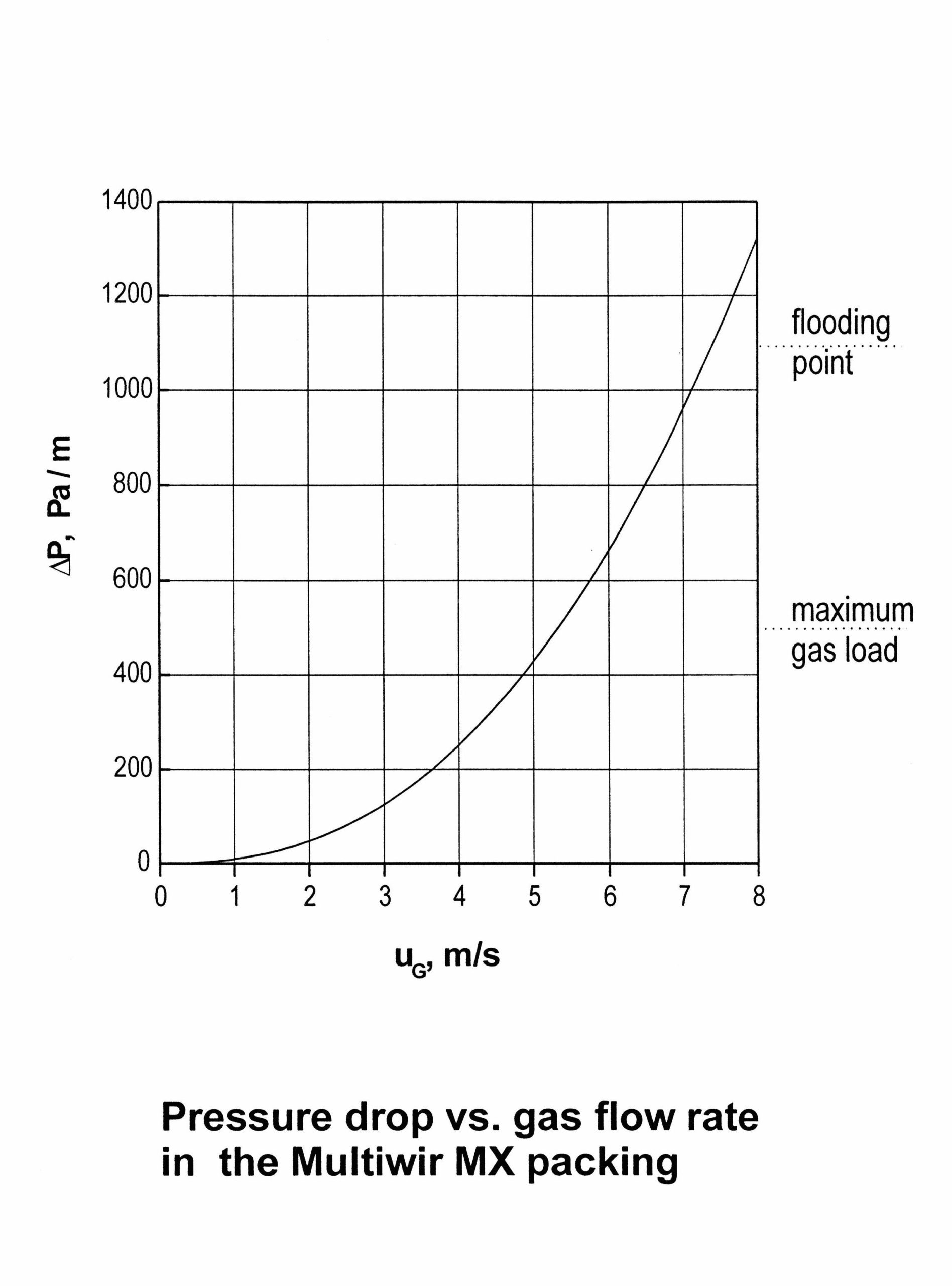

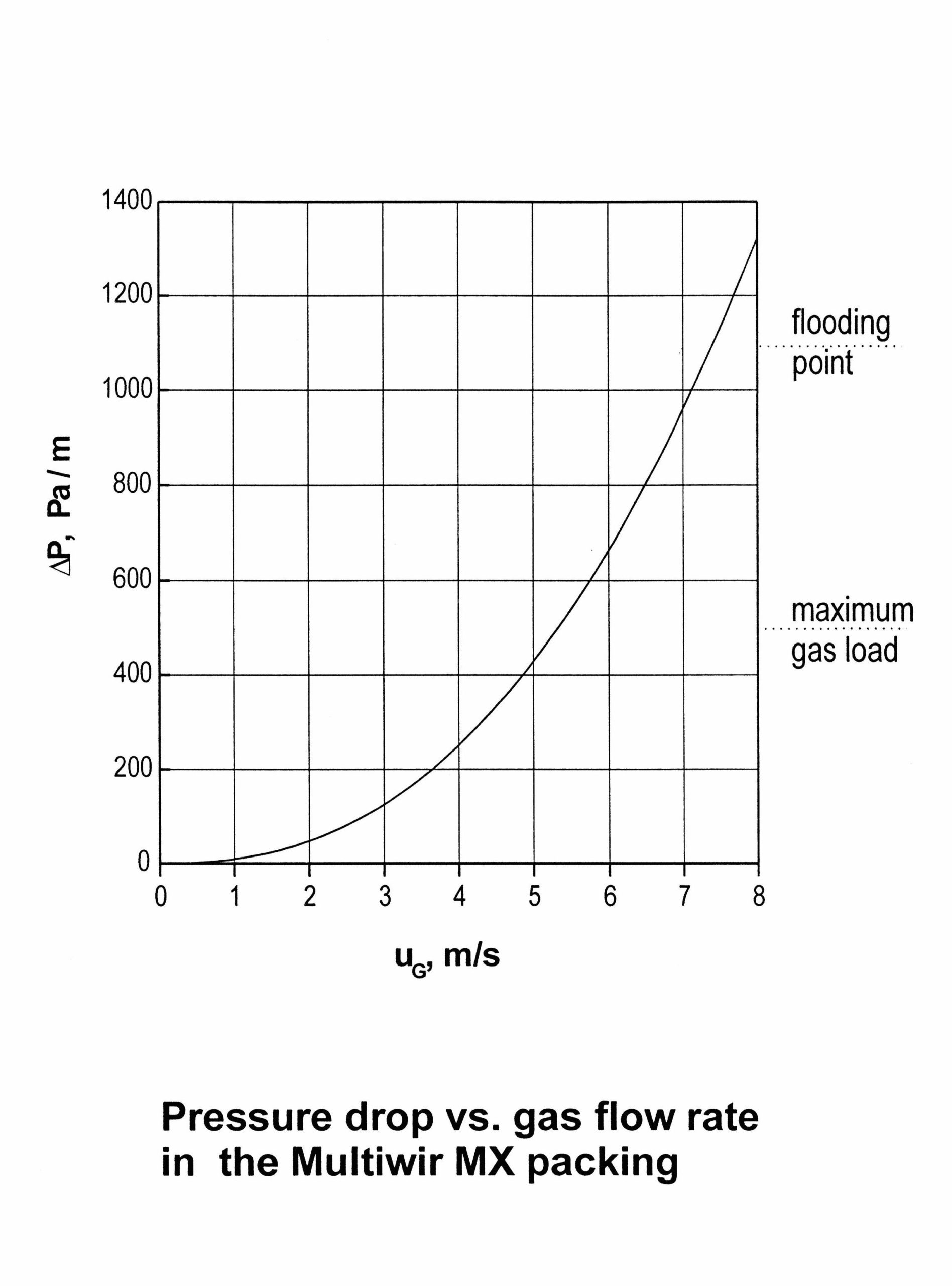

Multiwir MX packing is characterised by low pressure-drop. For that reason an application of a wide range of gas and liquid flow rates is possible. In the case of a countercurrent flow the gas velocity can safely reach 4,5 m/s without any risk of flooding. An additional advantage of the Multiwir MX packing is its high durability and mechanical strength.

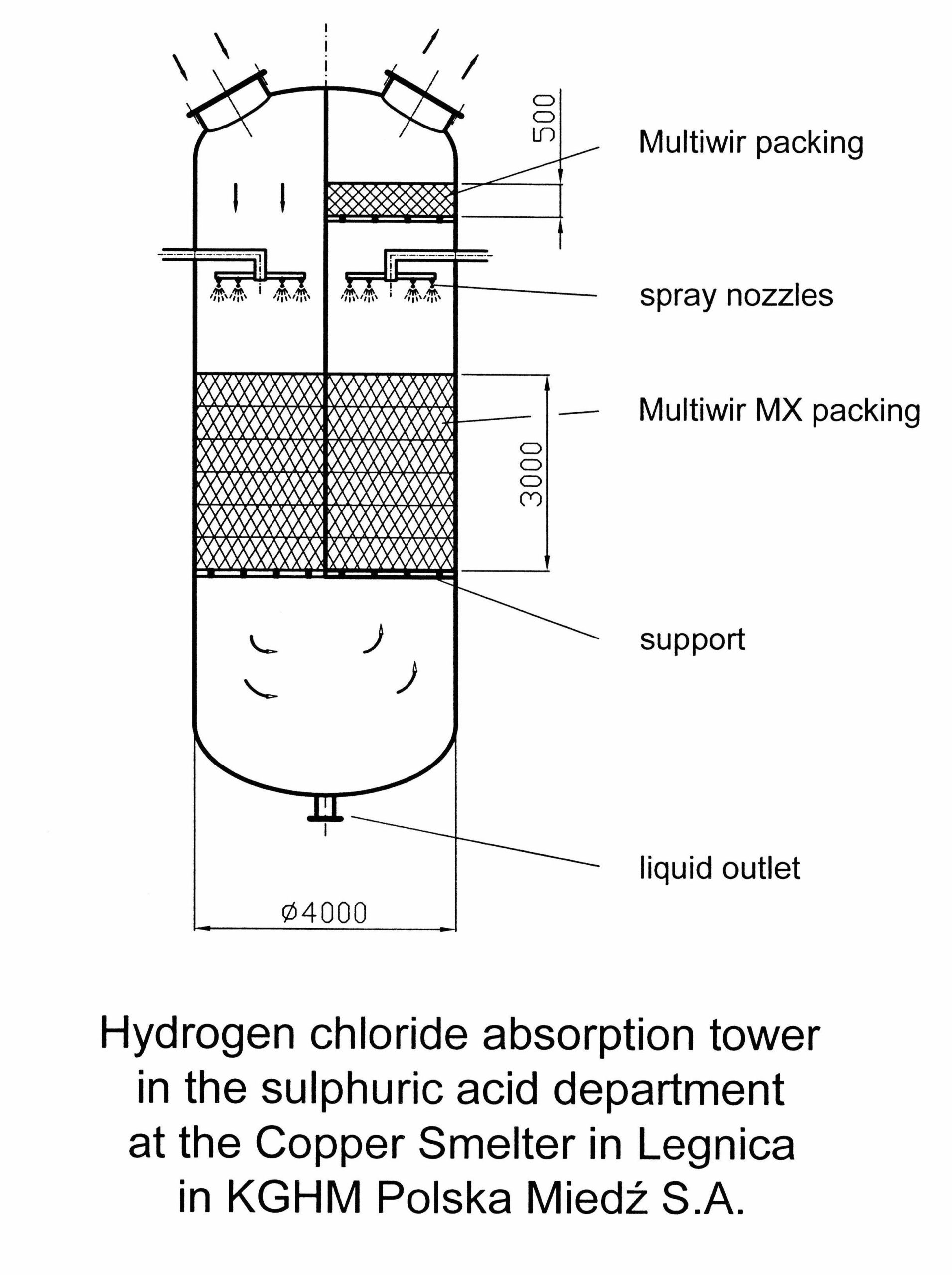

An example of the use of the Multiwir MX packing is the hydrogen chloride absorption installation operating since 1995 at the Legnica Copper Smelter (KGHM Polska Miedź) in the sulfuric acid department. Two identical devices operating in parallel are part of the Solinox installation for flue gas desulphurisation. Each device is a cylindrical column divided by a vertical partition into a co-current and counter-current section. Both sections are filled with Multiwir MX packing and equipped with spray nozzles. The total height of the MX packing in each of the two devices is 6 m. The counter-current part also contains a droplet separator in the form of a standard Multiwir packing placed at the top. The MX packing is sprayed with a circulating liquid with a chloride concentration of 1.5 ÷ 2.5 g/l without the addition of a neutralising agent. The gas velocity is 2,65 m/s. The average gas retention time inside the MX packing is 2,26 s. During this time, the installation absorbs an average of 185 mg of hydrogen chloride from each 1m3/s of gas. Thanks to the effective absorption of hydrogen chloride, the flue gas desulphurisation process in the SOLINOX installation is possible.